Vial Liquid Filling Production Line

Selelekela

Mochini oa tlhahiso ea ho tlatsa mokelikeli oa Vial o kenyelletsa mochini o hlatsoang o otlolohileng oa ultrasonic, mochini o omisang o omisang oa RSM, mochini o tlatsang le o emisang, mochini oa capping oa KFG/FG.Mohala ona o ka sebetsa hammoho le ho ikemela.E ka phethela mesebetsi e latelang ea ho hlatsoa ka ultrasonic, ho omisa & ho sterilizing, ho tlatsa le ho emisa, le ho koala.

Video ea Sehlahisoa

Kopo:

Bakeng sa tlhahiso ea vial ea khalase.

Mekhoa ea Tlhahiso:

Mohato oa 1

Ho hlatsoa ka lisebelisoa tsa motlakase

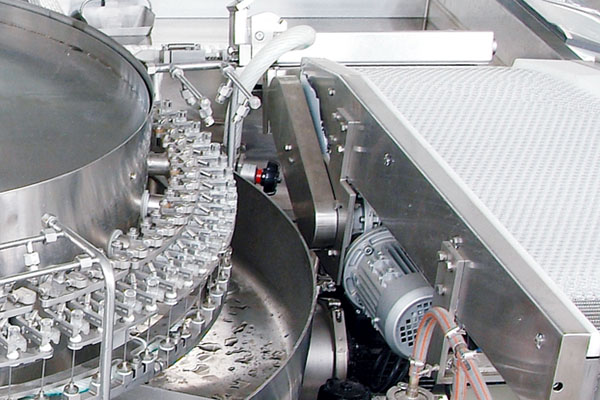

Mochini oa ho hlatsoa libotlolo oa Ultrasonic o sebelisoa ho hlakola kahare le kantle ho linkho tsa kalafo le libotlolo tse ling tsa li-cylinder.

E na le litšobotsi tse latelang: Net lebanta conveyor vials infeed sa khaotse;Qala ka ho fafatsa le ho hloekisa ka ultrasonic ho matlafatsa phello ea ho hloekisa.Tsamaiso e tsoelang pele ea ho potoloha.Sistimi ea motsamao, linkho tse ts'oaretsoeng ke letlapa le ikhethang la daemane.

Mokhoa o khothaletsoang oa ho hlatsoa: Setsi sa ho hlatsoetsa se 7 se abetsoe ka tsela e latelang:

NO.1 & No.2 station: Ho fafatsa ka hare le kantle ka metsi a potolohang.

NO.3 station: Ho foka ka hare ka moea o hatelitsoeng oa asepsis.

NO.4 seteishene: ho sebelisa WFI hloekisa ka hare ho vials.Seteisheneng sena, ho na le li-nozzles tse 'ne tse hlatsoang vial kantle.

NO.5 station: Ho foka ka hare ka moea o hatelitsoeng oa asepsis.

NO.6 seteishene: Ho fafatsa ka hare ka WFI.

NO.7 seteishene: Ho foka moea o hatelitsoeng oa asepsis ho ea ka hare ho vial habeli.Ka nako e ts'oanang, ho na le li-nozzles tse 'nè tse bululelang vial ka ntle.

Mohato oa 2

Ho omisa le ho omisa

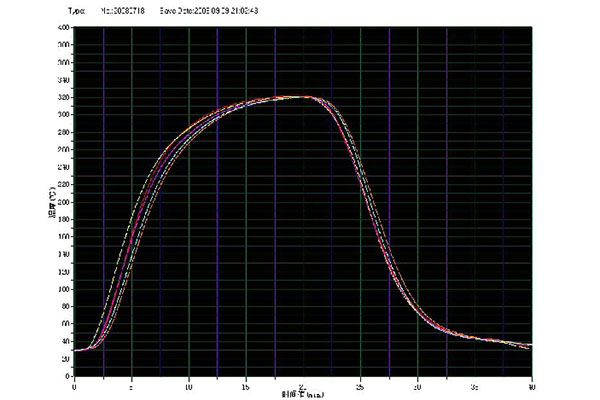

Laminar flow sterilization tonnel e sebelisetsoang ho hlatsoa linkho tse omeletseng le ho tlosa mocheso, E ka fihla mocheso o phahameng ka ho fetisisa oa 320 ℃, nako e sebetsang ea sterilization ho feta 7minutes. (bakeng sa 3Logs pyrogen redcution).

E na le libaka tse tharo tse sebetsang (Sebaka sa Preheat, sebaka sa ho futhumatsa, sebaka se phodileng).Libaka tse tharo tsa ts'ebetso tse kentsoeng holim'a poleiti ea motheo ea tšepe (bokaholimo bo tšoaroang ka chrome).Protective plate e sebelisoa AISI304 e neng e phekoloa ka mokhoa o khethehileng.

Mohato oa 3

Ho tlatsa le ho emisa

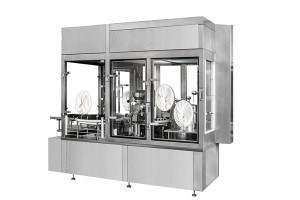

Aseptic Liquid Filling Machine ke mofuta o mocha oa vial filler o ntlafalitsoeng ke boithuto ba lihlahisoa tsa malapeng le kantle ho naha.E na le mefuta e fapaneng ea theknoloji e tsoetseng pele metheong ea ho kopanya le ho lelefatsa, 'me e sebetsa moleng oa tlhahiso.

Mohato oa 4

Capping

Capping Machine e loketse ts'ebetso ea ho tiisa vial ka cap ea aluminium.Ke mofuta o tsoelang pele oa mochini, ka disc e le 'ngoe ea capping e nang le melemo ea lebelo le phahameng, e senyehileng ka tlase ebile e khahla ponahalo.

Melemo ea Mohala oa Tlhahiso ea Liquid Liquid

1.The compact line e hlokomela khokahano e le 'ngoe, ts'ebetso e tsoelang pele ho tloha ho hlatsuoa, ho hloekisa le ho omisa, ho tlatsa le ho emisa, le ho koala.Ts'ebetso eohle ea tlhahiso e hlokomela ts'ebetso ea ho hloekisa;e sireletsa lihlahisoa ho tsoa tšilafalo, e kopana le maemo a tlhahiso ea GMP.

Taolo ea 2.Full servo.

3.Sekoahelo se sireletsang se ikemetseng se nang le moea o mongobo o nang le moea o mongobo, taolo ea screw ea motlakase, e sireletsehileng le e bonolo ho e hlokomela.

4.Bakeng sa meriana ea metsi ea bareki le litlhoko tsa ho tlatsa ho nepahala, ho khethiloe tsamaiso ea ho tlatsa pompo ea ceramic, e ka netefatsang ho nepahala ha ho tlatsa 'me e ka fetoha habonolo.

5.Mokhoa oa ho emisa oa ho kenya ha o ntse o potoloha o ka tiisa ka katleho phello ea ho emisa.

Mochine oa 6.Capping: Ha ho Vial - Ha ho Capping, Ha ho Stopper - Ha ho Capping, Vacuum monya sesebelisoa sa aluminium scrap.

Tlhophiso ea Mochini

Tech Parameters

| Mohlala | Mohala oa tlhahiso | Boholo bo loketseng | Sephetho(boholo) | Matla | Boima bo kahare | Boholo ka kakaretso |

| BXKZ ke | CLQ 40 | 2.25ml | 6000-12000 likhomphutha / h | 69.8KW | 7500Kg | 9930×2500×2340mm |

| RSM 620/44 | ||||||

| KGF 8 | ||||||

| BXKZII | CLQ60 | 2.25ml | 8000-18000 likhomphutha / h | 85.8KW | 8000Kg | 10830×2500×2340mm |

| RSM 620/60 | ||||||

| KGF10 | ||||||

| BXKZ III | CLQ80 | 2.25ml | 10000-24000 likhomphutha / h | 123.8KW | 8100Kg | 10830×2500×2340mm |

| RSM 900/100 | ||||||

| KGF 12 |

*** Hlokomela: Kaha lihlahisoa li lula li nchafatsoa, ka kopo ikopanye le rona bakeng sa lintlha tsa morao-rao.***

Moreki ea khabane